+604 332 2335

sales@professional-tools.com

Professional Tools & Dies Sdn Bhd (PTD) is a vertically integrated Contract Manufacturing partner specializing in five key areas: Mould Fabrication, Plastic Injection Molding, Sheet Metal Stamping, Box-build Assemblies, and Metal Fabrication. Moving beyond its initial focus solely on mold-making, the company now delivers comprehensive manufacturing solutions to Multinational Corporation (MNC) clients from America and European countries across diverse industries. With our state-of-the-art manufacturing facility, we are equipped to accelerate the release of customer products to market promptly and with uncompromising quality standards.

At PTD, we serve a wide range of markets with our comprehensive manufacturing solutions. Our clientele includes industries such as Automotive, Medical Devices, Electrical & Electronics, Telecommunication, Oil & Gas, and more. With our mechanical expertise and dedication to quality, we cater to the needs of each market segment, delivering precision-engineered components and products that meet and exceed industry standards.

Our commitment to excellence ensures that we remain a trusted partner for businesses across diverse sectors, helping them achieve their goals efficiently and effectively.

Founded in 1990, PTD began with a modest team of two employees. Over the years, our workforce has grown significantly, now comprising 300 dedicated professionals. This expansion has empowered us to effectively cater to a diverse global clientele spanning various industries.

At our core, we prioritize continuous improvement, investing in our facilities to ensure they align seamlessly with the exacting standards of our valued customers. Through ongoing enhancements, we fortify our capability to deliver excellence, empowering us to exceed expectations and drive mutual success.

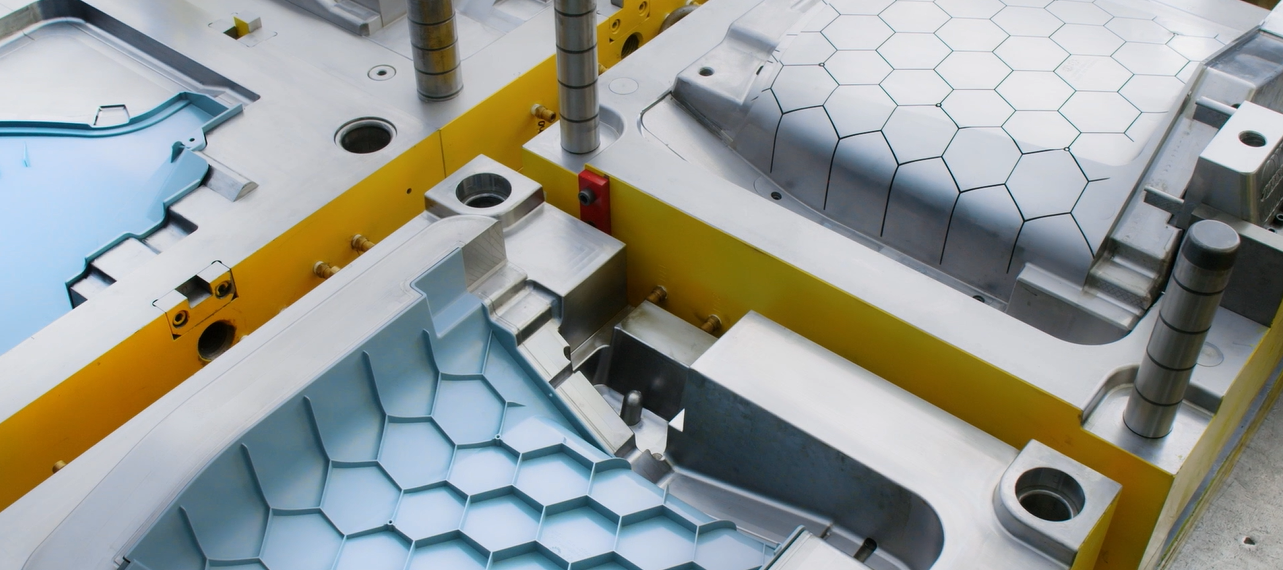

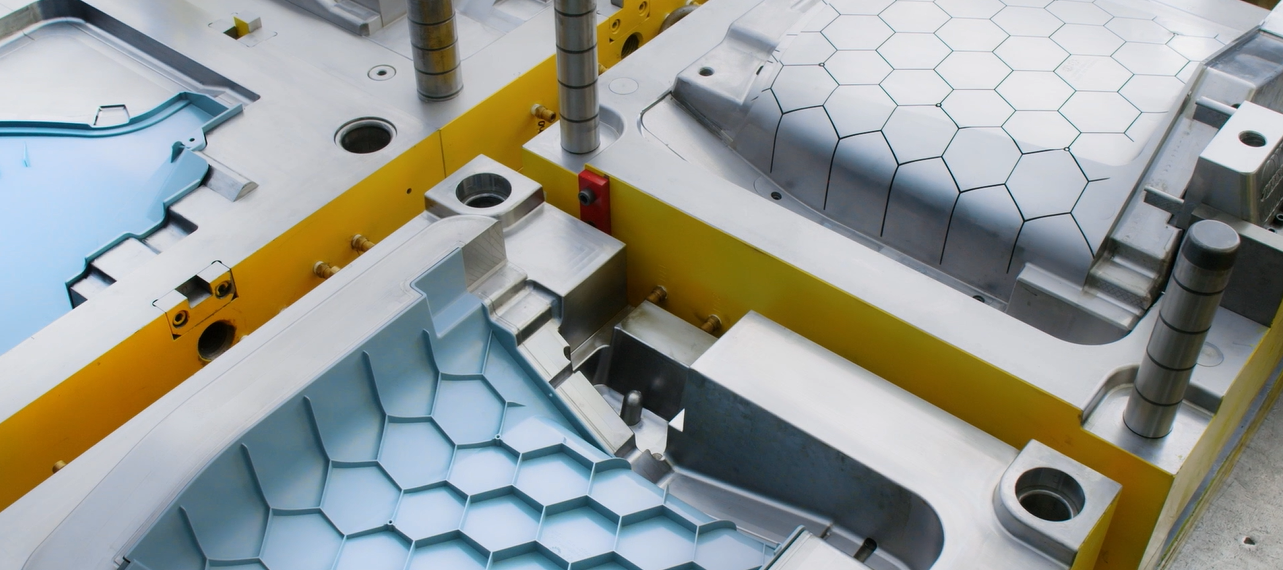

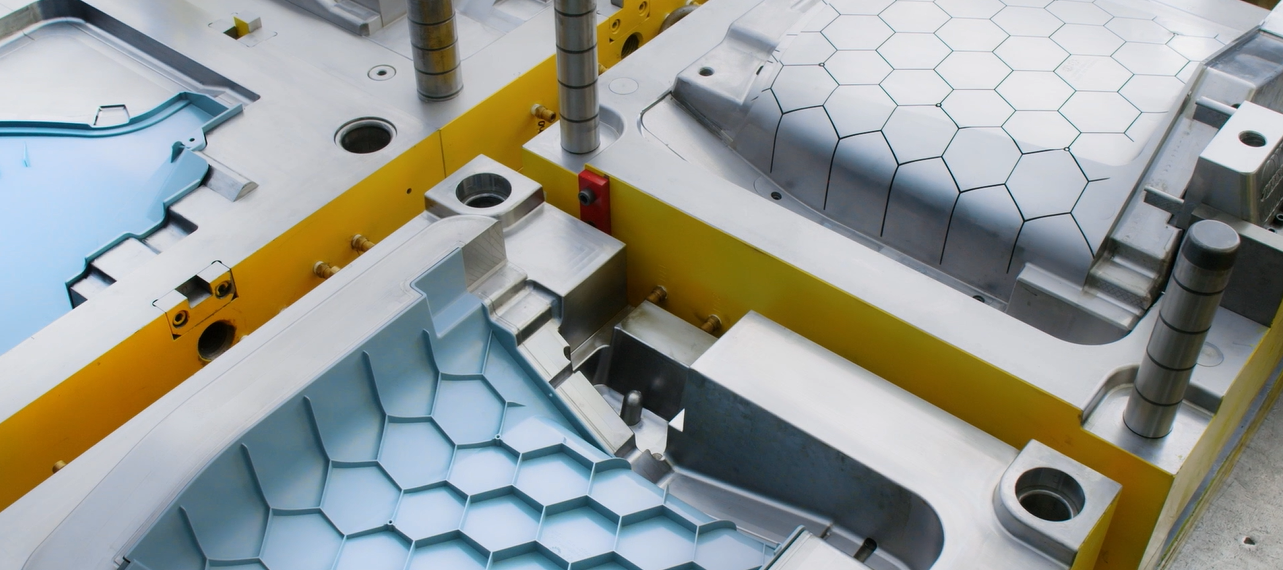

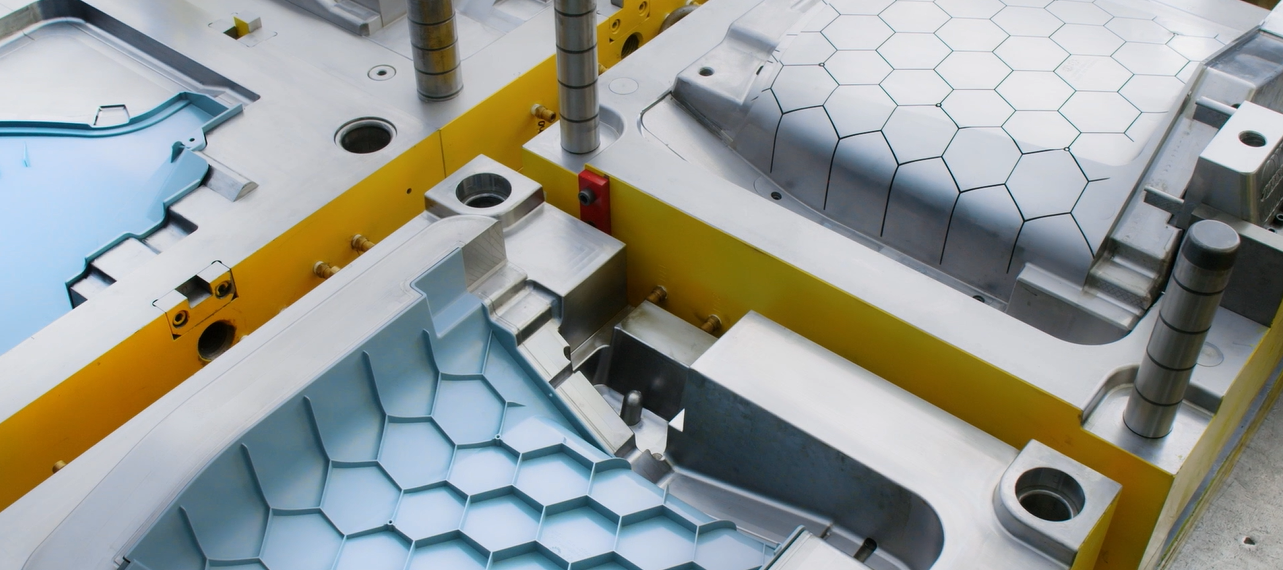

Step into our world-class production facility, where precision meets innovation at every turn. Equipped with state-of-the-art technology and driven by a commitment to excellence, we offer unparalleled capabilities to bring your visions to life with unmatched quality and efficiency. Experience the pinnacle of manufacturing expertise and elevate your production standards with us.

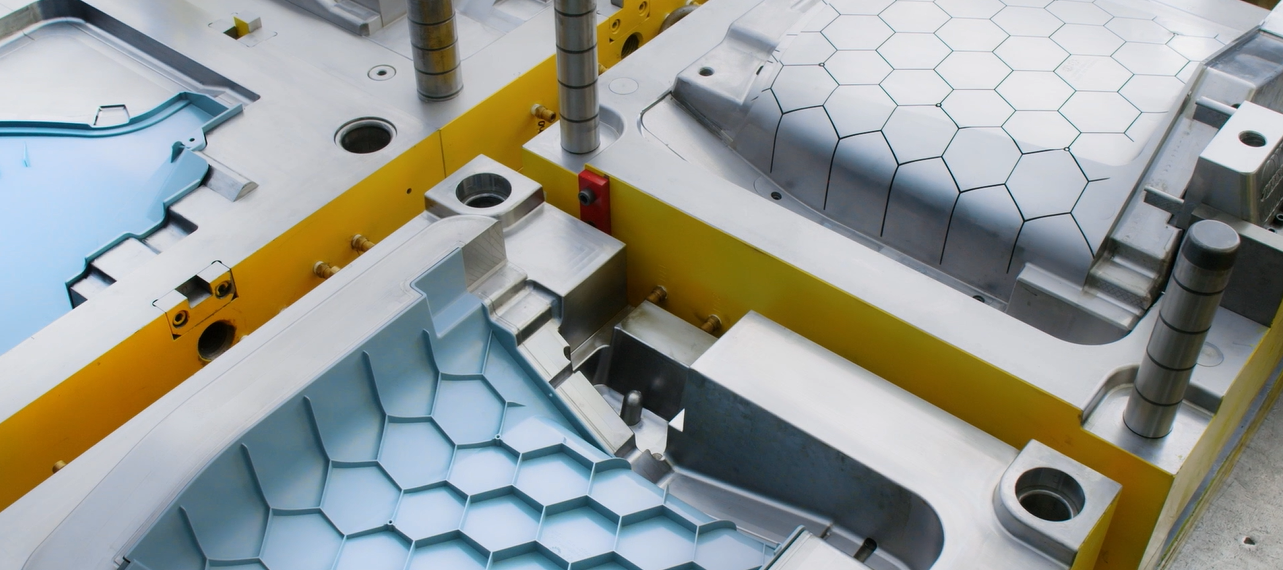

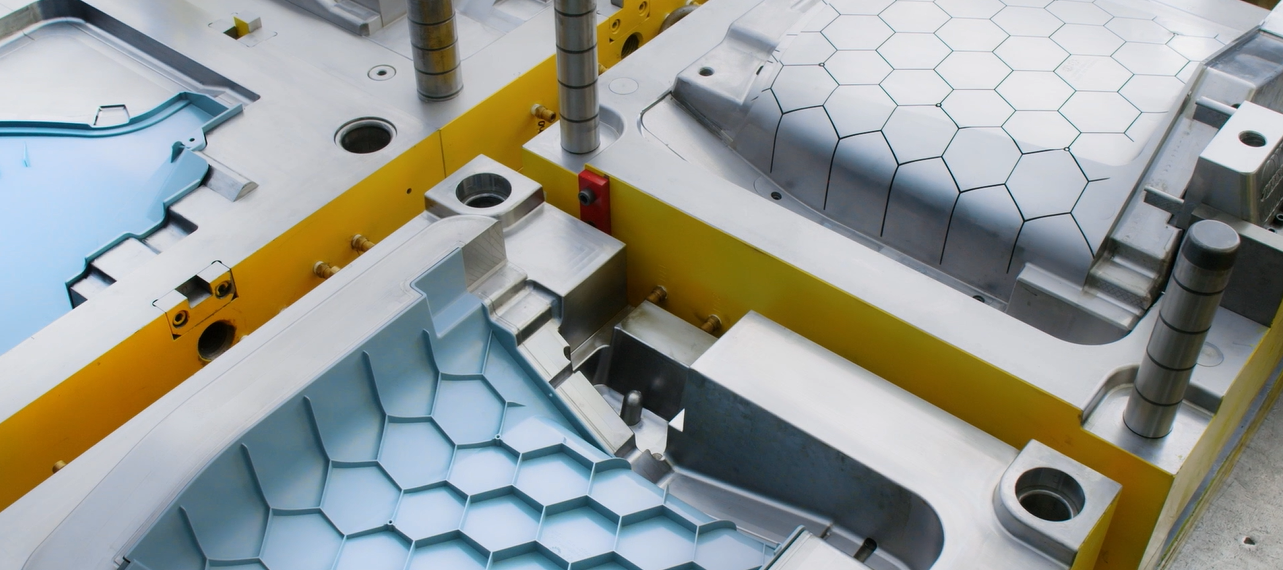

Unlock the potential of precision with our high-caliber injection molding and metal stamping capabilities. From intricate components to complex designs, our cutting-edge technology and meticulous craftsmanship ensure unmatched accuracy and reliability. Elevate your products to new heights of excellence with our expertise, setting the standard for precision manufacturing.

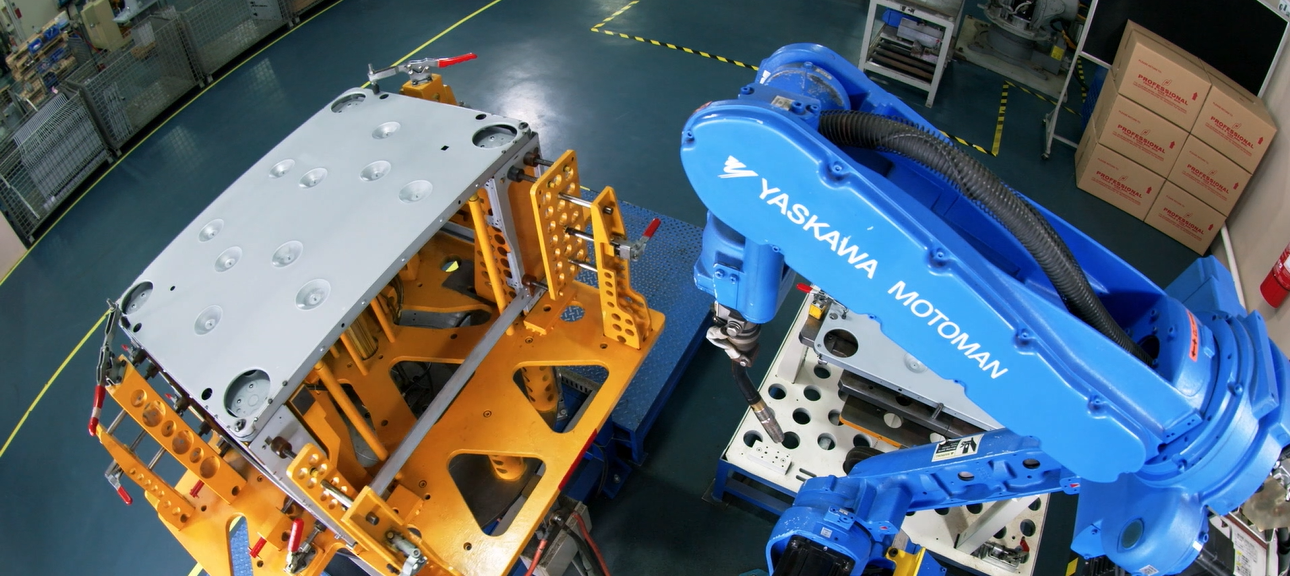

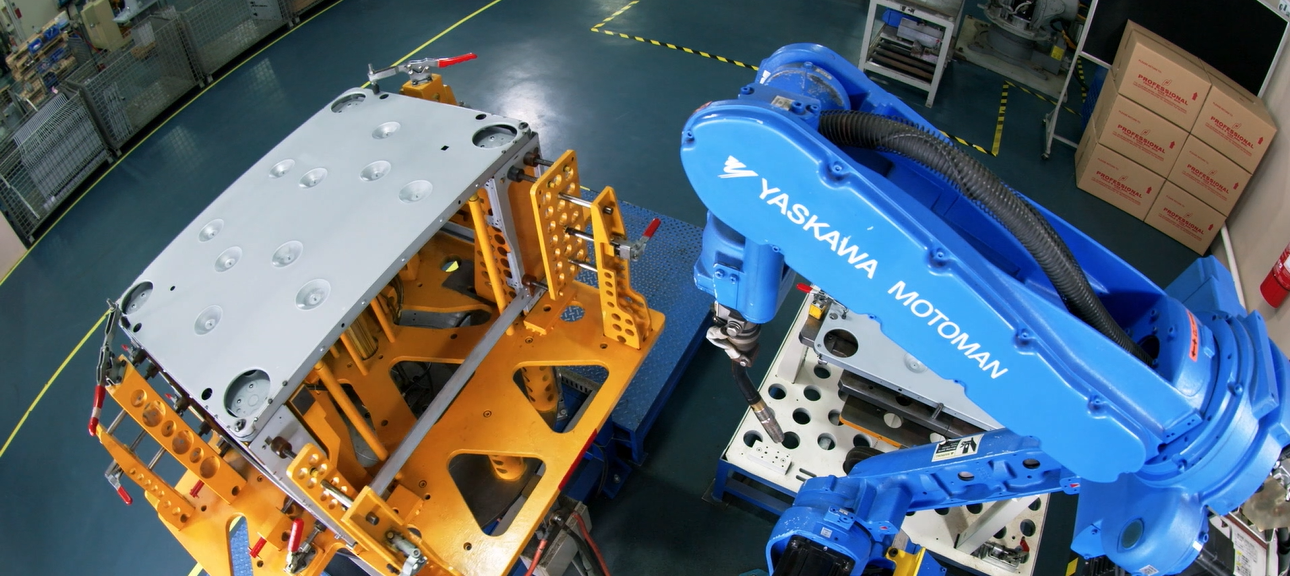

Embrace the future of manufacturing with our forward-thinking approach to production. By spearheading the integration of Industry 4.0 principles, we’re revolutionizing efficiency and precision through robotic automation and digitalization. Experience seamless workflows, heightened accuracy, and unparalleled agility as we lead the charge toward a new era of innovation in manufacturing.