+604 332 2335

sales@professional-tools.com

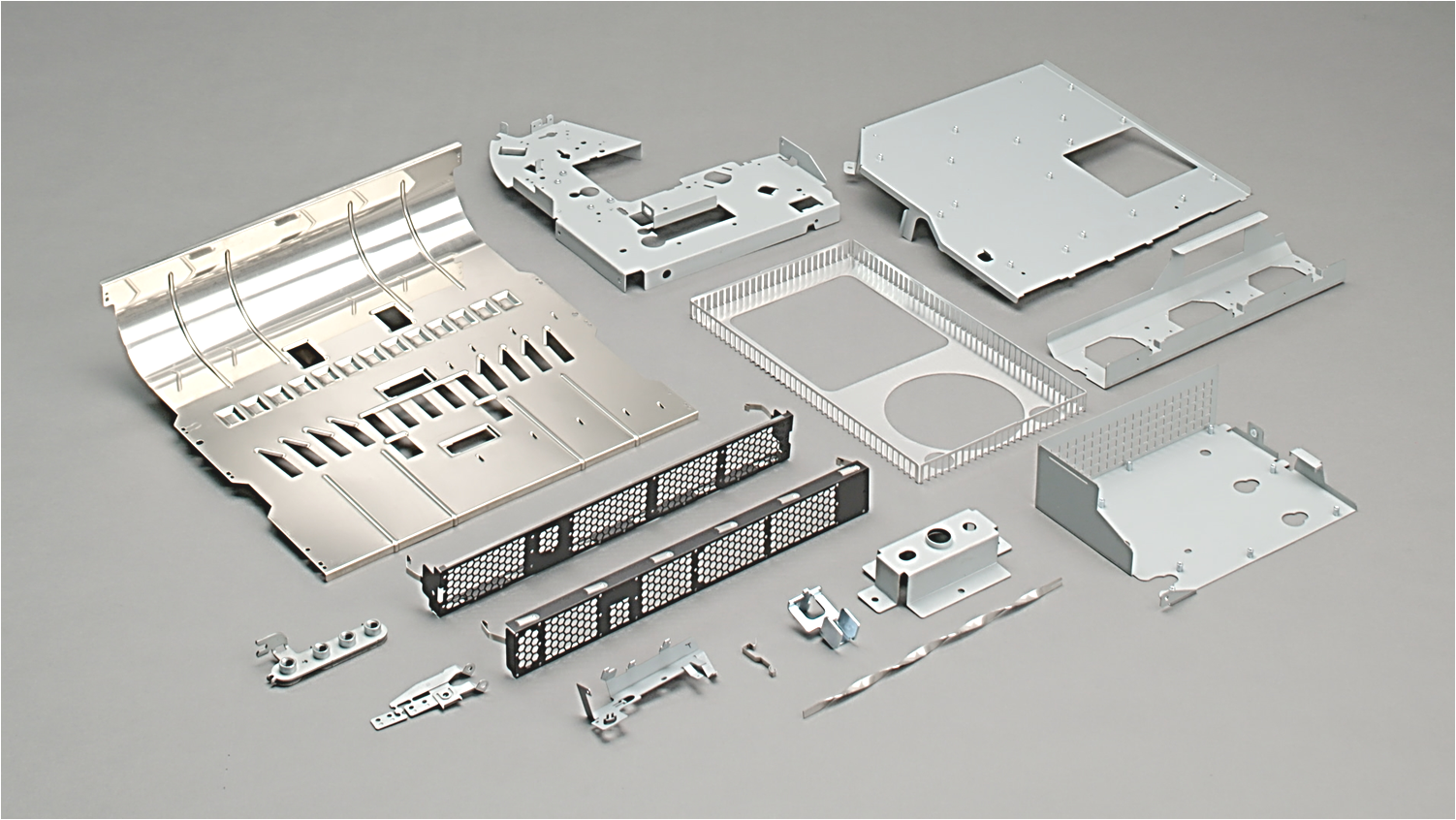

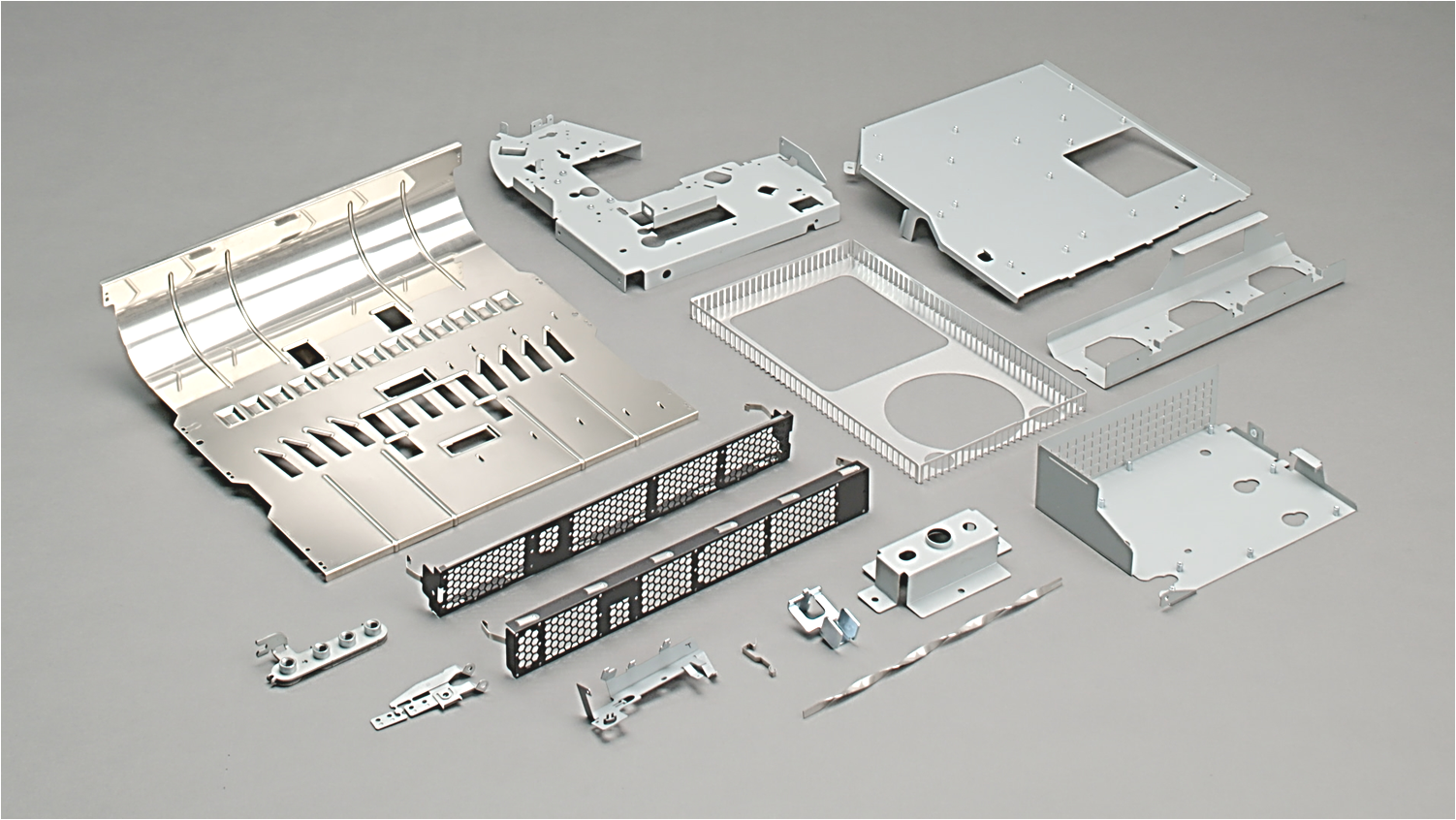

Sheet metal stamping at Professional Tools & Dies Sdn Bhd is a core manufacturing service that transforms flat metal sheets into precision-engineered panels and structures using high-tonnage presses and custom-designed dies. It’s a key part of their vertically integrated contract manufacturing model.

| Service | Key Features |

| Progressive Dies Stamping | Multi-stage forming, ±0.01mm accuracy |

| Single Station Stamping | Supports a range of operations including blanking, piercing, bending, forming, clinching, and coining |

| Short-Run Stamping | No MOQ, 1–10k parts |

| Robust Die Sets & Presses | Utilizes rigid die sets with precision-guided alignment to ensure consistent performance under high-pressure operations. |

| In-House Tool Maintenance | Equipped with a dedicated tool maintenance department to ensure dies remain in optimal condition for reliable, long-term use. |

| Support a vast range of secondary processes | MIG, TIG & Spot Welding, Clinching, Tapping, Spinning, Ultrasonic Cleaning & Riveting, Surface Finishing ( Spray & Plating ) |

Progressive dies perform multiple operations in sequence; compound dies do them in one stroke.