+604 332 2335

sales@professional-tools.com

Sheet Metal Fabrication Malaysia

Sheet metal fabrication at Professional Tools & Dies Sdn Bhd is a precision-driven process that transforms flat metal sheets / various shapes of tubes into functional components and assemblies — tailored for industries such as Semiconductor, Oil & Gas, Defense, Medical Devices Machine, and Industrial Equipment.

Advantages:

Project Execution:

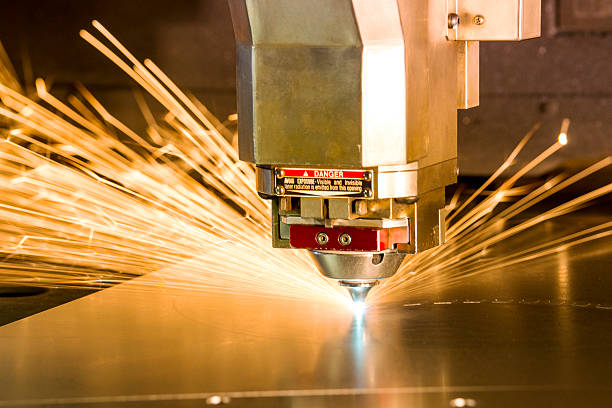

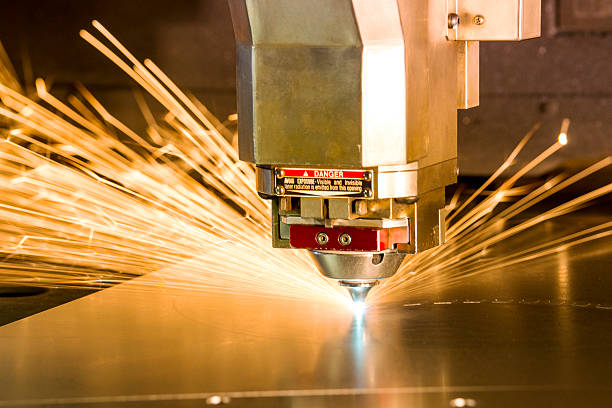

Process Flow: 1. Laser cutting → 2. CNC bending → 3. Secondary Processes → 4. Welding → 5. Powder coating, Spray Painting, or Plating

Technologies:

Not at all. We can make flat panels to long metal tubes products.

No, laser cutting is just one step in the broader sheet metal fabrication process.

Not always. Many designs rely on mechanical fasteners, riveting, or snap-fit techniques.