+604 332 2335

sales@professional-tools.com

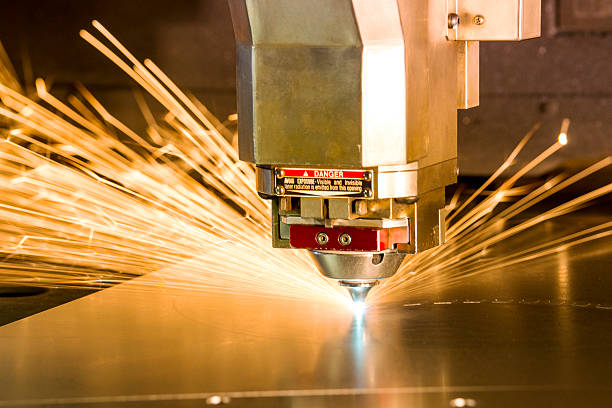

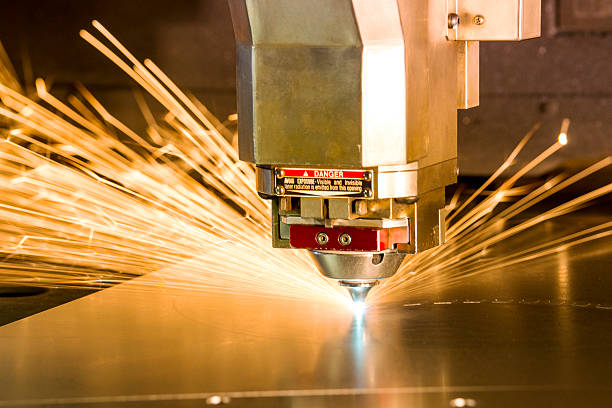

In today’s competitive manufacturing landscape, precision and efficiency are no longer optional, they are essential. One of the most advanced technologies driving this progress is fibre laser cutting. For industries in Malaysia that rely heavily on sheet metal fabrication, fibre laser cutting offers unmatched accuracy, speed, and cost-effectiveness.

At Professional Tools, we specialize in providing end-to-end manufacturing solutions, and fibre laser cutting plays a vital role in delivering quality products for diverse industries such as automotive, electronics, medical, and industrial equipment.

Fibre laser cutting is a manufacturing process that uses a highly focused laser beam, delivered through fibre optics, to cut through sheet metals with extreme precision. Unlike traditional cutting methods, fibre lasers provide:

This technology has become a cornerstone in modern sheet metal fabrication because it reduces waste, saves time, and ensures consistent quality.

Malaysia’s manufacturing industry is fast-growing, with companies demanding cost-efficient and high-quality sheet metal parts. Fibre laser cutting provides a competitive edge by meeting these demands with precision and consistency.

Benefits for Malaysian Manufacturers

Sheet metal fabrication in Malaysia often requires processes like cutting, bending, stamping, and welding. Among these, cutting forms the foundation. Fibre laser cutting ensures that subsequent processes, such as bending or welding, are more accurate because the initial cuts are precise.

This makes fibre laser cutting the preferred method for industries requiring both precision and efficiency.

Fibre laser cutting is widely applied across various sectors:

The versatility of this process ensures it can adapt to the unique needs of different industries in Malaysia.

At Professional Tools, we bring together state-of-the-art equipment, skilled expertise, and end-to-end manufacturing capabilities. Our fibre laser cutting services are designed to support projects of all sizes, from prototypes to high-volume production.

What Sets Us Apart?

As industries demand higher standards of accuracy and faster turnaround, fibre laser cutting will continue to shape the future of sheet metal fabrication in Malaysia. With its unmatched precision, efficiency, and sustainability benefits, this technology is an investment in long-term competitiveness.

At Professional Tools, we remain committed to driving innovation and supporting Malaysia’s manufacturing sector with advanced solutions.

Fibre laser cutting has revolutionized sheet metal fabrication in Malaysia, providing manufacturers with the precision, speed, and cost-effectiveness needed to stay ahead in a global market. Whether for automotive, electronics, medical, or industrial applications, fibre laser cutting ensures that every cut counts.

If you are looking for a trusted partner in fibre laser cutting and sheet metal fabrication in Malaysia, Professional Tools is here to deliver solutions that exceed expectations.

Fibre laser cutting is versatile and can process:

Professional Tools offers:

Disclaimer Statement

We hope you found this article informative. Our content is intended for general informational purposes only and does not constitute advice or necessarily reflect the full range of services offered by Professional Tools & Dies Sdn. Bhd.

Readers are advised to consult with a qualified industry professional and contact our experts for tooling’s recommendations specific to their individual project needs. While we strive for accuracy and completeness in our blog posts, we cannot guarantee they are error-free. Professional Tools & Dies Sdn. Bhd. assumes no responsibility for any errors or omissions.