+604 332 2335

sales@professional-tools.com

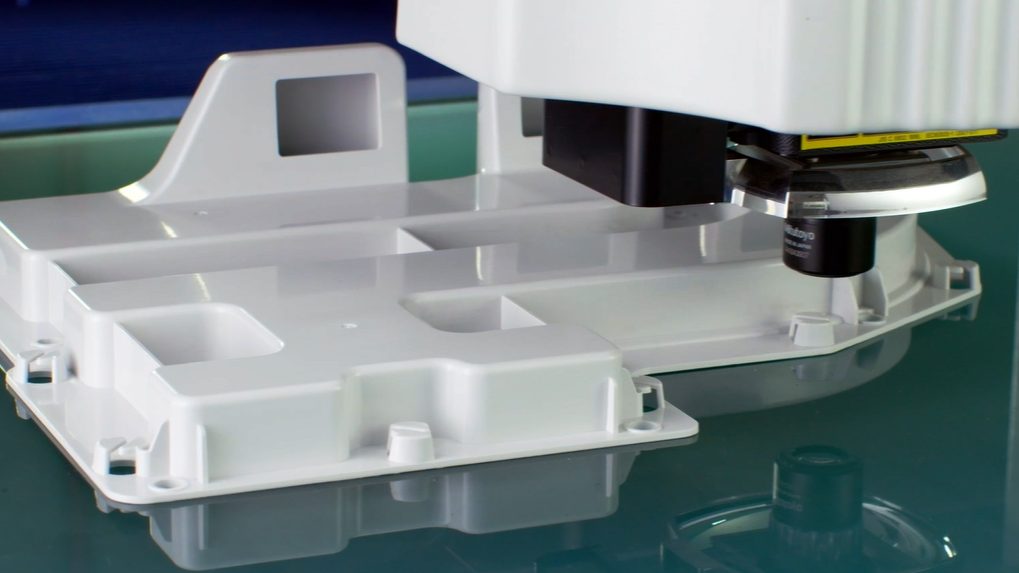

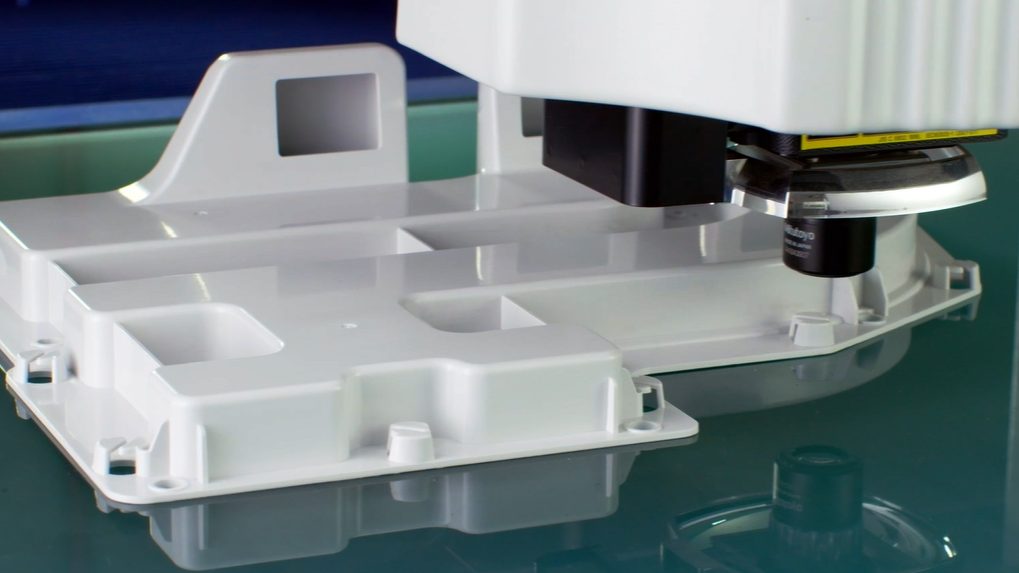

In today’s competitive manufacturing environment, businesses in Malaysia are under constant pressure to deliver high-quality products with greater efficiency. Achieving this balance often relies on investing in specialized workholding solutions. One of the most effective ways to secure accuracy and consistency is through the use of jigs and fixtures.

At Professional Tools, our expertise in Jigs and Fixtures Malaysia enables manufacturers to streamline operations while meeting the exacting standards of modern production.

Jigs and fixtures are not just support tools; they are essential for ensuring repeatability and accuracy in every production run.

Together, these custom tools drastically reduce operator error, cut down on cycle time, and guarantee that each part meets the same exact specifications. For industries where precision directly impacts product safety and reliability, these benefits are indispensable.

Businesses in Malaysia are increasingly turning to customized tooling to address the challenges of high-volume, precision-driven production. The tangible advantages include:

|

Advantage |

Benefit |

Quantification |

| Consistent Quality | Guarantees product conformity across every batch. | Zero Defect Assurance for critical components. |

| Increased Throughput | Faster turnaround time due to reduced manual adjustments and quicker setup. | Potential 15-30% reduction in cycle time. |

| Cost Savings | Minimized errors, rework, and scrap material waste. | Typical ROI within 6 to 12 months on high-volume runs. |

| Enhanced Safety | Securing workpieces minimizes movement, protecting personnel and machinery. | Improved compliance with workplace safety standards. |

For companies in high-tech sectors like Automotive, Electronics, and Medical Devices, these advantages directly translate into stronger competitiveness in both local and international markets.

The versatility of jigs and fixtures makes them vital in a wide range of industries. With Professional Tools’ expertise, they are applied in areas such as:

Professional Tools specializes in designing and fabricating high-precision jigs and fixtures tailored to specific industry needs. We offer a vertically integrated solution, ensuring quality and efficiency from concept to delivery.

Our capabilities include:

The future of manufacturing in Malaysia will increasingly rely on automation, precision, and cost efficiency. Custom jigs and fixtures will remain at the heart of this transformation, enabling businesses to deliver world-class products while optimizing operations.

At Professional Tools, our tooling solutions are designed to meet these evolving demands, ensuring you stay ahead in today’s competitive environment.

Contact Professional Tools today for a customized consultation on how our precision tooling and workholding solutions can guarantee accuracy and efficiency in your next project.

Jigs and fixtures are widely used in:

Custom tooling enhances efficiency by:

Key factors include:

The timeline depends on project complexity. Generally:

The choice of material depends on the application, durability needs, and production environment. Common options include:

Disclaimer Statement

We hope you found this article informative. Our content is intended for general informational purposes only and does not constitute advice or necessarily reflect the full range of services offered by Professional Tools & Dies Sdn. Bhd.

Readers are advised to consult with a qualified industry professional and contact our experts for tooling’s recommendations specific to their individual project needs. While we strive for accuracy and completeness in our blog posts, we cannot guarantee they are error-free. Professional Tools & Dies Sdn. Bhd. assumes no responsibility for any errors or omissions.