+604 332 2335

sales@professional-tools.com

In the evolving landscape of precision manufacturing, CNC machining and turning have become essential processes that define the quality, accuracy, and reliability of modern components. In Malaysia, the growing demand for high-tolerance parts across automotive, electronics, and medical sectors underscores the need for experienced partners who can deliver exceptional precision.

At Professional Tools, we combine advanced machining technology, skilled engineering, and stringent quality control to provide reliable CNC Machining Turning Malaysia solutions tailored to industrial performance requirements.

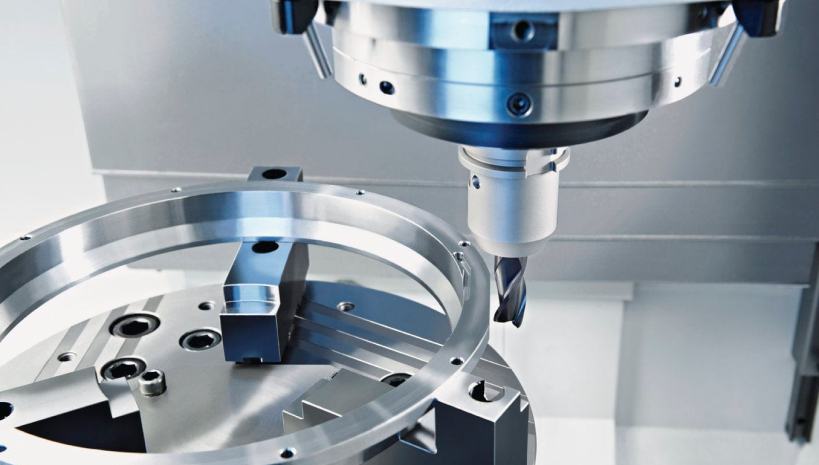

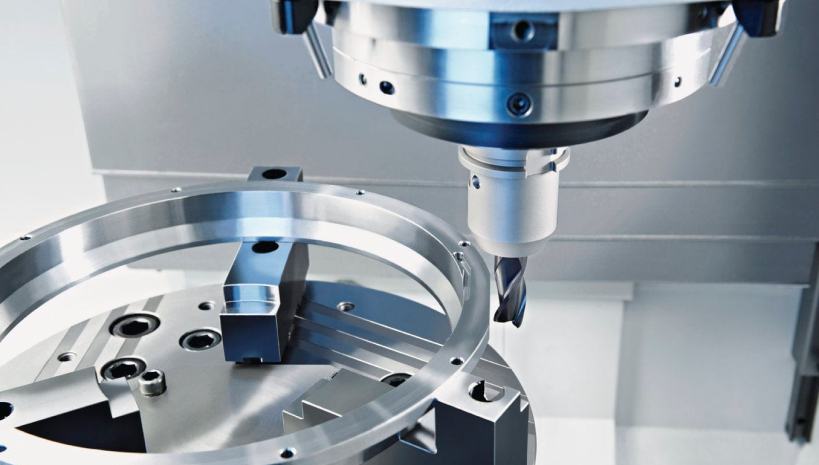

CNC (Computer Numerical Control) machining and turning are processes that use automated equipment to shape materials with high accuracy and repeatability.

These technologies eliminate human error, increase production speed, and ensure that every component meets exact specifications – a crucial advantage for industries requiring tight dimensional control.

Precision and consistency are at the heart of competitive manufacturing. CNC technology ensures every production cycle achieves the same level of quality, regardless of volume or complexity.

Key benefits include:

These advantages make CNC machining and turning indispensable for manufacturers aiming to balance precision with productivity.

Professional Tools offers complete in-house solutions that integrate precision engineering, process control, and advanced tooling expertise. Our CNC machining and turning services are supported by modern facilities and experienced technicians dedicated to maintaining consistent quality and dimensional accuracy.

Our capabilities include:

By integrating precision machining, tooling design, and process optimization, we deliver components that meet the exact specifications of demanding industries.

CNC technology supports a wide range of industrial operations across Malaysia’s growing manufacturing ecosystem.

Our machining and turning capabilities are vital for:

Through precision engineering and strict process discipline, Professional Tools continues to be a trusted partner for industries that demand accuracy, consistency, and reliability.

At Professional Tools, we understand that successful manufacturing depends on both technology and expertise. Our team ensures that every CNC-machined or turned component not only meets dimensional standards but also aligns with your operational goals. With advanced equipment, dedicated process control, and proven engineering experience, we help clients achieve optimal efficiency and performance in every production stage.

Whether it’s a prototype, a custom part, or a high-volume production run, our focus remains on delivering uncompromising precision and value.

The future of precision manufacturing in Malaysia depends on smart integration of advanced technology and expert craftsmanship. With CNC machining and turning, Professional Tools enables industries to produce high-quality components that meet the demands of modern engineering.

Contact Professional Tools today to discuss your CNC Machining Turning Malaysia requirements and discover how we can help elevate your production capabilities with precision-driven solutions.

We maintain consistency through:

This combination allows every batch to meet identical dimensional tolerances from start to finish.

Our advantage lies in the integration of CNC machining, CNC turning, and precision tooling design within one facility. This reduces communication gaps, shortens lead times, and ensures design-to-production alignment, a key benefit that few standalone machining providers can offer.

Yes. We’re structured for scalability:

This flexibility ensures consistent quality at every manufacturing stage.

We use multi-axis CNC machines, advanced CAD/CAM programming, and detailed process simulation before production begins. Combined with real-time measurement and skilled technicians, we consistently meet tolerance requirements even in intricate or high-precision designs.

Our precision engineering solutions serve sectors that demand both reliability and compliance, including:

Each project is supported by our engineering team to meet specific quality and certification requirements.

Disclaimer Statement

We hope you found this article informative. Our content is intended for general informational purposes only and does not constitute advice or necessarily reflect the full range of services offered by Professional Tools & Dies Sdn. Bhd.

Readers are advised to consult with a qualified industry professional and contact our experts for tooling’s recommendations specific to their individual project needs. While we strive for accuracy and completeness in our blog posts, we cannot guarantee they are error-free. Professional Tools & Dies Sdn. Bhd. assumes no responsibility for any errors or omissions.