+604 332 2335

sales@professional-tools.com

Situated in close proximity to Penang Silicon Valley, our operations are housed within a spacious 400,000-square-foot facility on a 10-acre plot of land. This strategically located facility is conveniently just a 30-minute drive from Penang International Airport. Within this facility, we house all our essential business support units, including Engineering, Quality Control, and Supply Chain Management. From this central hub, we establish global connections to various destinations worldwide. We are vertically integrated to handle:

Machinery frame fabrication

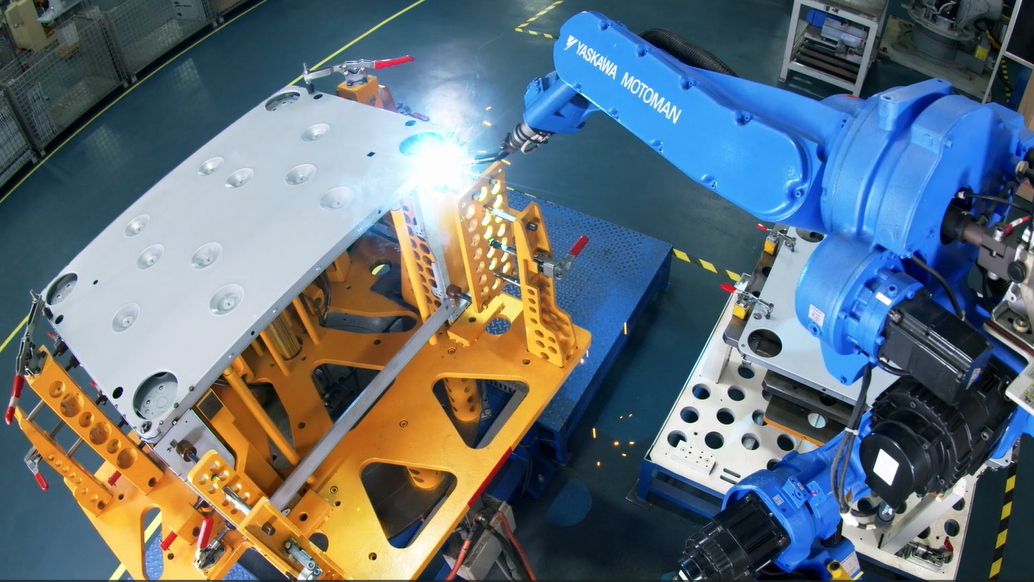

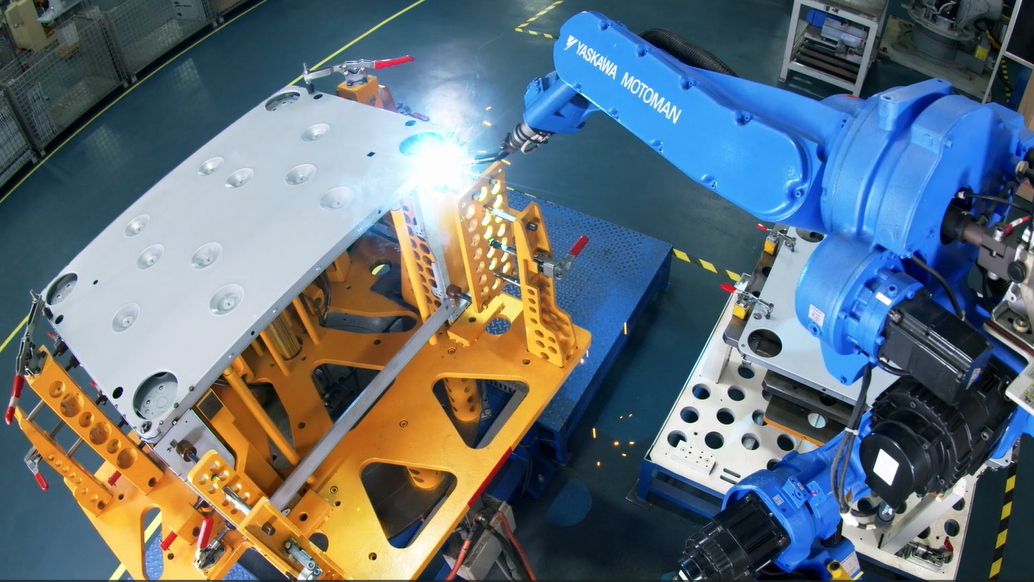

Welding and robotic welding systems

CNC machining and turning

Surface finishing and heat treatment

Sheet metal bending and laser cutting

Precision assembly for box-build and modular structures

Our plant is designed to support high-volume and custom structural fabrication projects with a focus on heavy-duty machine frames, industrial enclosures, base plates, panels, and complex mechanical structures.