+604 332 2335

sales@professional-tools.com

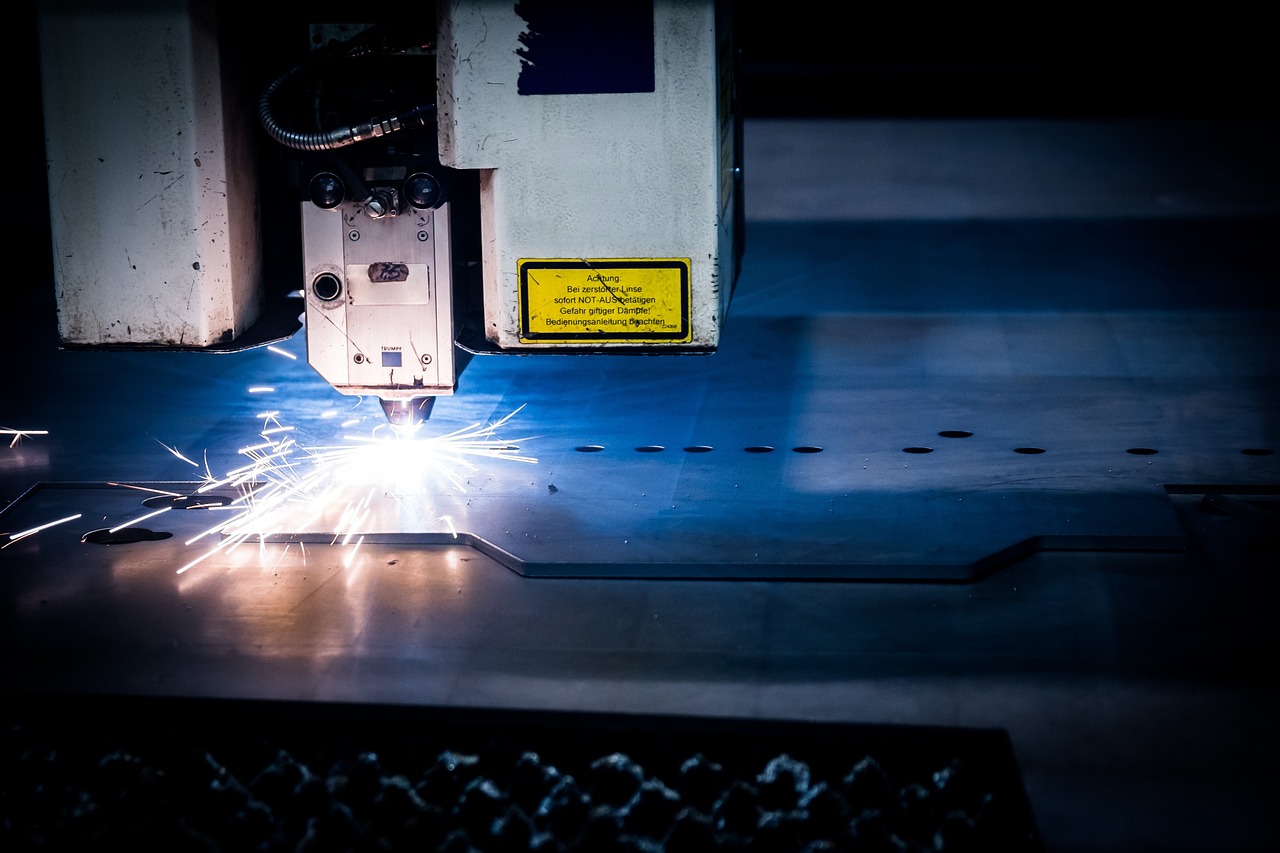

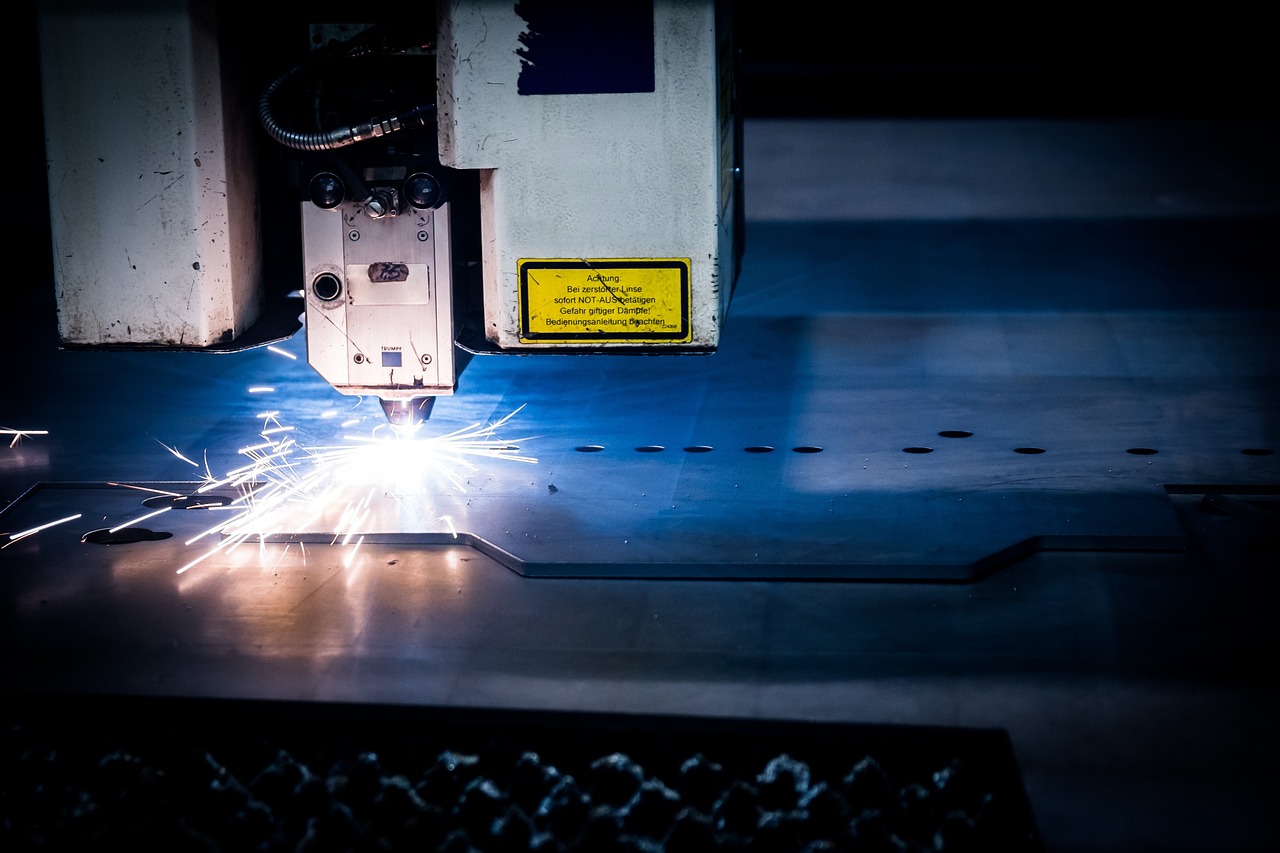

From Laser Cutting to Bending: Sheet Metal Fabrication Techniques in Malaysia

Confused about the techniques involved?

Trying to figure out which process fits your project?

Or just wondering why precision matters so much?

Sheet metal fabrication is the backbone of industries like construction, electronics, and automotive. But with so many techniques, it’s hard to know what’s what.

Sheet metal fabrication is the process of turning flat sheets of metal into usable products or parts. Think car bodies, electronic enclosures, or industrial machinery.

It’s precise, efficient, and cost-effective for large-scale production.

And Malaysia becoming a global hub for this expertise.

Here are the techniques you need to know:

Why it’s popular in Malaysia: High-quality results at competitive costs.

Fun Fact: Malaysia’s manufacturing sector relies heavily on this for custom projects.

Big Advantage: Less human error means better results and lower costs.

Pro Tip: Stamping reduces waste, which keeps costs down.

Here’s why Malaysia is leading the game:

Sheet metal fabrication in Malaysia is all about precision, quality, and affordability.

Whether it’s laser cutting, bending, or welding, there’s a technique for every project.

Start with laser cutting or press brake bending for precision.

For large-scale production? Robotic welding is the way to go.

Want to learn more about how this works?

Explore more on Sheet Metal Stamping and Fabrication Techniques.

Sheet metal fabrication is the process of converting flat metal sheets into functional parts or structures using techniques such as cutting, bending, forming, welding, and assembly. In Malaysia, modern fabrication methods often incorporate computerized numerical control (CNC) and laser cutting to achieve high precision and tight tolerances.

Professional tools provide a variety of services including CNC punching, laser cutting, bending, forming, welding, and finishing. Many firms offer a one‑stop service—from material selection and design consultation to final assembly—ensuring products meet both industry standards and client specifications.

Common material used stainless steel, aluminum, carbon steel, and copper. They are durable, versatile, and cost-effective.

The duration based on factors such as design complexity and order volume and required customization. Simple project might be completed within couple of weeks, while complex and custom finishes could take loner. Do consult with our professional team for accurate estimate timelines.

Disclaimer Statement

We hope you found this article informative. Our content is intended for general informational purposes only and does not constitute advice or necessarily reflect the full range of services offered by Professional Tools & Dies Sdn. Bhd.

Readers are advised to consult with a qualified industry professional and contact our experts for tooling’s recommendations specific to their individual project needs. While we strive for accuracy and completeness in our blog posts, we cannot guarantee they are error-free. Professional Tools & Sdn. Bhd. assumes no responsibility for any errors or omissions.